Essential Kegerator Coupler Parts for Your Home Brew Setup

Ever wondered why your draft beer sometimes pours foamy or flat? Those issues often trace back to the little parts that bridge your keg and tap. An improper setup can strip even premium brews of their carbonation and flavor.

At Installation Parts Supply, we know that a smooth pour starts with quality hardware. Whether you’re a homebrewing enthusiast or just love fresh draft beer, understanding these keg tap parts pieces ensures every glass is served just right.

From washers to gas lines, each part plays a role in maintaining pressure and flavor. More than nine out of ten pour problems stem from mismatched or worn parts. A little knowledge goes a long way in keeping your system running flawlessly.

Core Lessons

- Proper coupler selection ensures optimal beer flow and flavor.

- Installation Parts Supply offers dependable draft-system hardware.

- Keeping parts clean and checked avoids typical pouring glitches.

- Various brews call for particular coupler designs.

- Coupler faults are behind most draft system breakdowns.

Kegerator Coupler: An Overview

A flawless draft begins with the proper keg-to-tap link. Think of the keg coupler as the connector between your CO₂ cylinder or nitrogen tank and the beer line, employing pressurized gas to deliver beer flawlessly to your taps. Think of it as the engine of your draft beer system—without it, nothing flows.

It both pumps gas in to pressurize your keg and regulates how the beer exits. Its interior consists of a probe, a check valve, and distinct ports for beer and gas. Each part ensures your brew stays carbonated and pours without foam.

| Part | Role | Common Issues |

|---|---|---|

| Probe | Punctures the keg seal | Leaks if not aligned properly |

| Check Valve | Stops beer from flowing backward | Flat pours from worn seals |

| Gas/Liquid Ports | Connects to lines | Foaming from loose connections |

Misconnecting the coupler is a common error—three out of four novices slip up. That leads to foam floods, leaks, and ruined beer. Check Installation Parts Supply’s charts and videos for correct setup.

Even “universal” styles need to correspond with your keg’s standards. A mismatched setup won’t just ruin your pour; it could damage your equipment.

Types of Keg Couplers and Their Uses

Different beers call for different couplers. Using the proper coupler keeps your beer fizzy and flavorful. Follow this guide to choose the right one.

Standard D System Coupler

This is the go-to for 85% of North American craft beers. Its single-valve design locks securely onto most domestic kegs. Pro tip: Look for the Sankey name stamped on the side.

Nitro (U) Coupler

Recognizable by its harp logo, this type is a must for nitro beers like Guinness. It uses a unique gas blend (75% nitrogen) to create that creamy head. Don’t jam a U-style onto a regular keg—no proper seal results.

S System (European Sankey) Coupler

Imports from Europe require this S-system coupler. The left-hand twist prevents mix-ups with D Systems. It’s roughly an inch taller than the U.S. version.

Specialty European Couplers

Certain European brews need these specific coupler types:

- A-Type Coupler: Fits Paulaner and Warsteiner kegs perfectly. That slider lock never slips.

- G-Type Coupler: Tri-flat stem locks onto Bass & Boddingtons. A pub staple across the UK.

- M-Type Coupler: Made for Schneider Weisse kegs. The slide-lock clicks when secure.

Installation Parts Supply’s chart uses green=D, black=U, blue=S. One Midwestern brewery cut costs by $3K annually with the right couplers. Always favor exact compatibility over “universal” marketing.

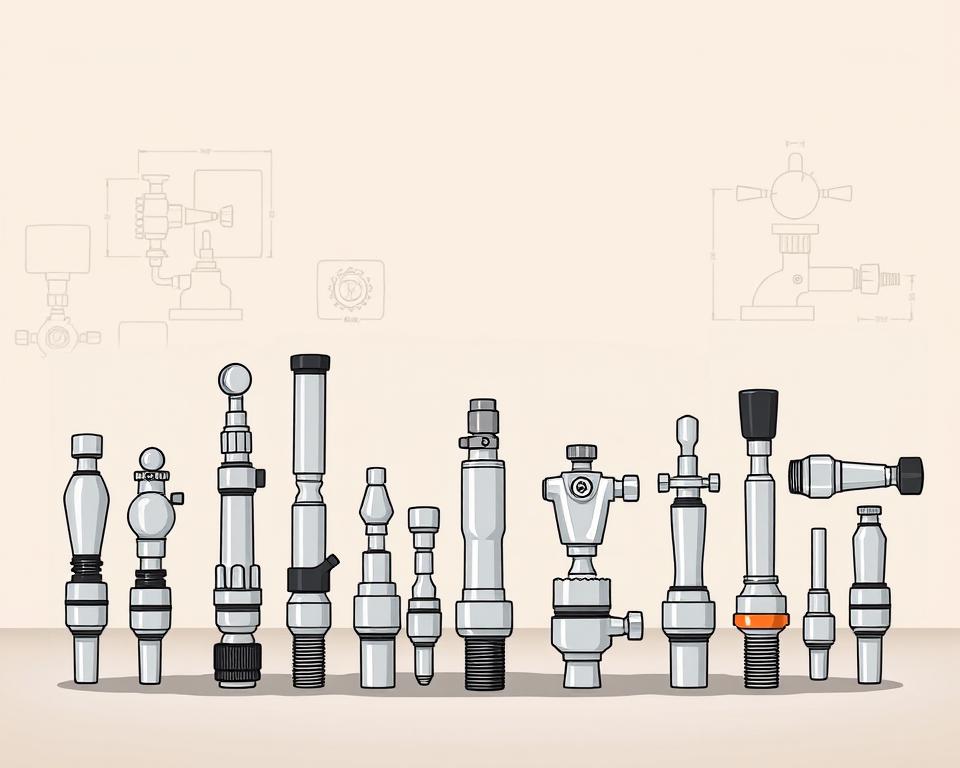

Key Coupler Components Explained

Smooth flows come from well-crafted coupler pieces. Together, they keep carbonation in and foam out. Let’s break down the key hardware that keeps your system running.

Coupler Probe & Check Valve

The stainless steel probe pierces the keg’s seal, controlling beer flow. High-end probes outlast budget ones by threefold. The check valve below prevents backflow and is our most swapped component.

Nut and Washer Assembly

Everything tightens up around the hex nut. Brass is economical; stainless fights rust. Use nitrile washers in the cold—EPDM fails below 40°F.

| Part | Construction | Key Benefit |

|---|---|---|

| Coupler Probe | SS | Resists wear |

| Return Valve | FDA-approved plastic | Stops foam issues |

| Coupler Nut | Brass/Stainless | Cost-effective & durable |

Gas & Beer Ports

The gas port handles 20–30 PSI for CO₂ or nitrogen. Mismatched pressure causes foam. Liquid ports work best with 3/16″ ID tubing—1/4″ lines increase turbulence. Rebuild kits with FDA seals simplify maintenance.

Pro Tip: Replace O-rings biannually or after ~50 kegs. A cheap washer swap saves you from a costly rebuild.

How to Set Up Your Kegerator Coupler

Install correctly for flawless drafts. Right setup stops foam and leaks. Here’s how to hook it up without hiccups.

Attaching Coupler to Keg

Raise the lever, line up the lugs with slots. Turn clockwise until snug—over-tightening damages the seal. Choose low-profile to gain 4–5″ clearance.

Our wrench sets hex nuts to the ideal 8-10 ft-lb. A misaligned probe causes 80% of leaks. Never reuse old washers.

Line Connections

Hook the gas line on with 5/16″ fittings. Apply thread sealant to prevent CO₂ leaks. For beer lines, 10–12 feet of 3/16″ tubing balances pressure drop.

| Step | Equipment | Note |

|---|---|---|

| Gas Line | Pipe dope | Check with 30 PSI leak test |

| Draft Line | Tubing cutter | Cut straight for proper seals |

| Leak Test | Soapy water | Check for 24 hours |

Modern rigs offer app-based pressure feedback. A Denver brewery cut foam by 40% using quick-connects from Installation Parts Supply. Turn off gas immediately if you spot big leaks.

Coupler Troubleshooting

A foam burst spoils your draft faster than anything. Most pouring problems stem from simple fixes once you know where to look. Below are common faults and quick fixes.

Foamy Beer Solutions

Sixty-eight percent of draft issues are foam-related. Start by checking your temperature—ideally 38°F for most ales. Warm beer releases CO₂ prematurely.

Check each draft line connection next. Soap test any fitting—bubbles point to leaks. Use a wrench to snug loose parts, avoiding over-torque.

- Ball Check Valve may hiss and interrupt flow

- Pressure imbalance? Compare your gauge to this chart:

| Beer Type | CO₂ PSI | Nitrogen Mix |

|---|---|---|

| Pilsners | 10–12 | N/A |

| Stouts | 25–30 | 75% nitrogen |

Coupler Fit Problems

If your coupler fits loosely, first check for worn O-rings. Our data shows O-ring swaps resolve 40% of loose fits. If the face is warped, swap the entire coupler.

For uneven surfaces, try keg shims. These inexpensive plastic wedges stabilize wobbling connections. Low-profile models solve clearance problems in compact coolers.

Pro Tip: Their emergency washer kit contains five critical seals. Staff who learned these tips reduced waste by nearly 20% in Chicago.

Remember—frost on your CO₂ tank signals overuse. Defrost before tweaking the relief valve. Digital gauges need yearly calibration for accuracy.

Maintenance for Your Coupler

A clean draft system means crisp, fresh-tasting beer every pour. Leftover yeast and oils harm both taste and pouring. A quick cleaning regimen prevents issues.

Disassembly and Soaking

First, disassemble the coupler. Remove the handle, probe, and check valve. Let the parts sit in warm PBW solution (1 oz/gallon) for 15–20 minutes. It dissolves yeast and hop deposits.

Our brushes get into the smallest crevices. Don’t forget the ball valve—it accumulates debris. Rinse thoroughly to avoid soapy aftertastes.

Best Coupler Cleaners

Powdered Brewery Wash excels at safe cleaning. Acid cleaners work faster but can damage rubber over time. Ultrasonic cleaners remove buildup in pro bars.

- Air Drying: Use compressed air or microfiber cloths.

- Sanitizing: Follow FDA CFR 117 guidelines—30 seconds of contact time kills bacteria.

- Record-Keeping: Use a log sheet to record each cleaning.

UV sanitation guards seals longer. Always neutralize wastewater—PBW is alkaline and harms pipes. Routine cleaning maximizes lifespan and taste.

Conclusion

Enjoy crisp, fresh beer by mastering your draft beer system. Choose compatible parts, maintain them well, and install correctly. Installation Parts Supply offers lifetime support and seasonal discounts on rebuild kits to keep your pours perfect.

Did you know? Routine care can extend your equipment’s life by 7 years. Get their checklist and attend a brewmaster session for insider advice. An annual check-up guarantees smooth service—just listen to customers with five years of trouble-free use.

Time to level up: head to Installation Parts Supply and improve your home bar.